Specially designed for sanding thickness of board bottom, this machine is widely used in various furniture, wood door, cabinet, veneer and painted surface. Bottom surface sanding machine can work together with other sanding machine. Such production line is mainly for the clients with large-scale.

When the board top surface is sanded by other sander, its bottom surface is next sanded by DSG1350R-RPA with fixed thickness after passing through conveyor table. Such connecting use can polish two surfaces at one time, not only reducing the labor cost but also increasing production efficiency, which is your first choice for updating.

Perfect Features

1. Widely used in the fine polishing of various furniture, wooden door, cabinet, board veneer and painted surface. It can work together with bottom surface sanding machine and is your first choice for updating.

2. The machine frame is made of thick rectangle steel tube by welding. It become more sturdy and durable after heat treatment, which is beneficial to reduce vibration when working and ensure the sanding precision.

3. Made of high quality manganese steel, the beam is hard to break or bend, which ensures the sanding stability.

4. Tested by dynamic balance, the calibrating precision of high speed roller is from 1g to 3g, 20% higher than the national standard. As a result, S-shaped grain is avoided and a higher sanding precision is guaranteed.

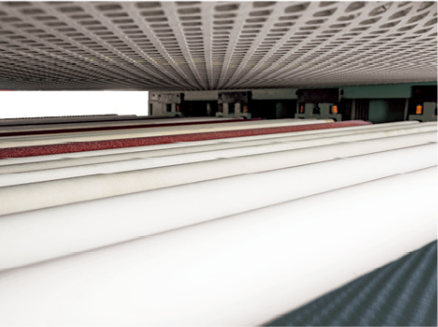

5. Three press rollers with different diameter as the feeding structure guarantees the sanding flatness and precision.

6. Vacuum table on the bottom surface sander can delivery the board more smoothly, stably and firmly .

7. The conveyor table is processed by mirror finishing, as a result it has a high flatness. So that the table remains stable and excellent precision without deformation when processed by high temperature.

1) Rational structure design |  |

2) Mechanical welding ---Automatic welding by mechanical hand ---Heat treatment ---Thick Rectangular steel pipe |  |

3) Dynamic balance test ---Rollers tested by dynamic balance machine ---Calibrating precision from 1g to 3g |  |

4) Conveyor table surface |  |

5) Feeding structure ---Specially design for bottom surface sanding machine ---Smooth and stable delivery for the board |  |

6) Vacuum table ---Increase the stability and firmness during feeding. |  |

7) Bearing |  |

8) Photo eye ---Super penetrability |  |

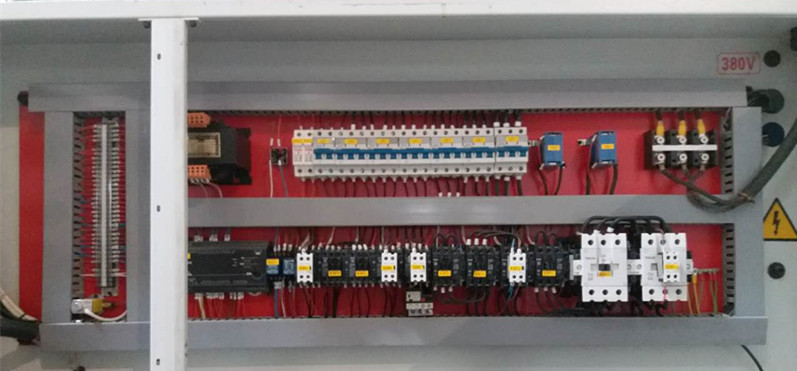

9) PLC |  |

10)Electric components ---Brand Siemens ---Quality guarantee |  |

11) Triangle belt |  |

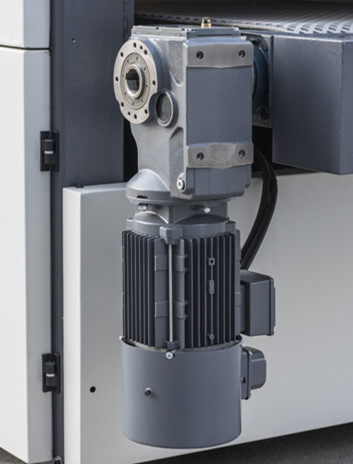

12) Gearbox |  |

<

| 1) Processed data | Working width: 40-1350mm | Working thickness:5-100mm | Min.working length: 450mm |

| 2) Sanding roller diameter | First roller φ240mm | Second roller φ180mm | |

| 3) Running speed | Conveyor belt: 0-19m/min(inverter) | ||

| First roller: 22m/s | Second roller: 16m/s | ||

| 4) Size of belt | Sanding belt: 1380x1900mm | Conveyor belt: 1360x3750mm | |

| 5) Motor power | Total motor power: 46.49kw | ||

| First belt motor: 22kw | Second belt motor: 15kw | ||

| Feeding motor: 3kw | Lifting motor: 0.37kw | Brush motor: 0.25kw | |

| Blower motor: 0.025kw | |||

| 6) Size | Overall size: 2200*2100*2050mm | Vacuum table exhaust outlet diameter φ120*1 | Dust outlet diameter: φ200*2 φ150*3 |

| 7) Weight | About 4050kg | ||

| 8) Others | Working pressure: 0.4-0.8Mpa | Compressed air consumption: 1m³/min | Average speed of sucked air: >30m/s |

Address: Hongxiang Er Road, Jinling Industry Park, Chengyang, Qingdao, 266111, China

Domestic sales:+86-532-87909872

International sales:+86-532-87909872

Mobile/ Wechat/ Whatsapp: +86 13608989908

Fax:+86-532-87909875

www.giantway.com

Email:sales.b@giantway.com