Mainly used on polishing uneven boards, including furniture, wooden doors, cabinets. Four individual modular working units can suit different materials for polishing.

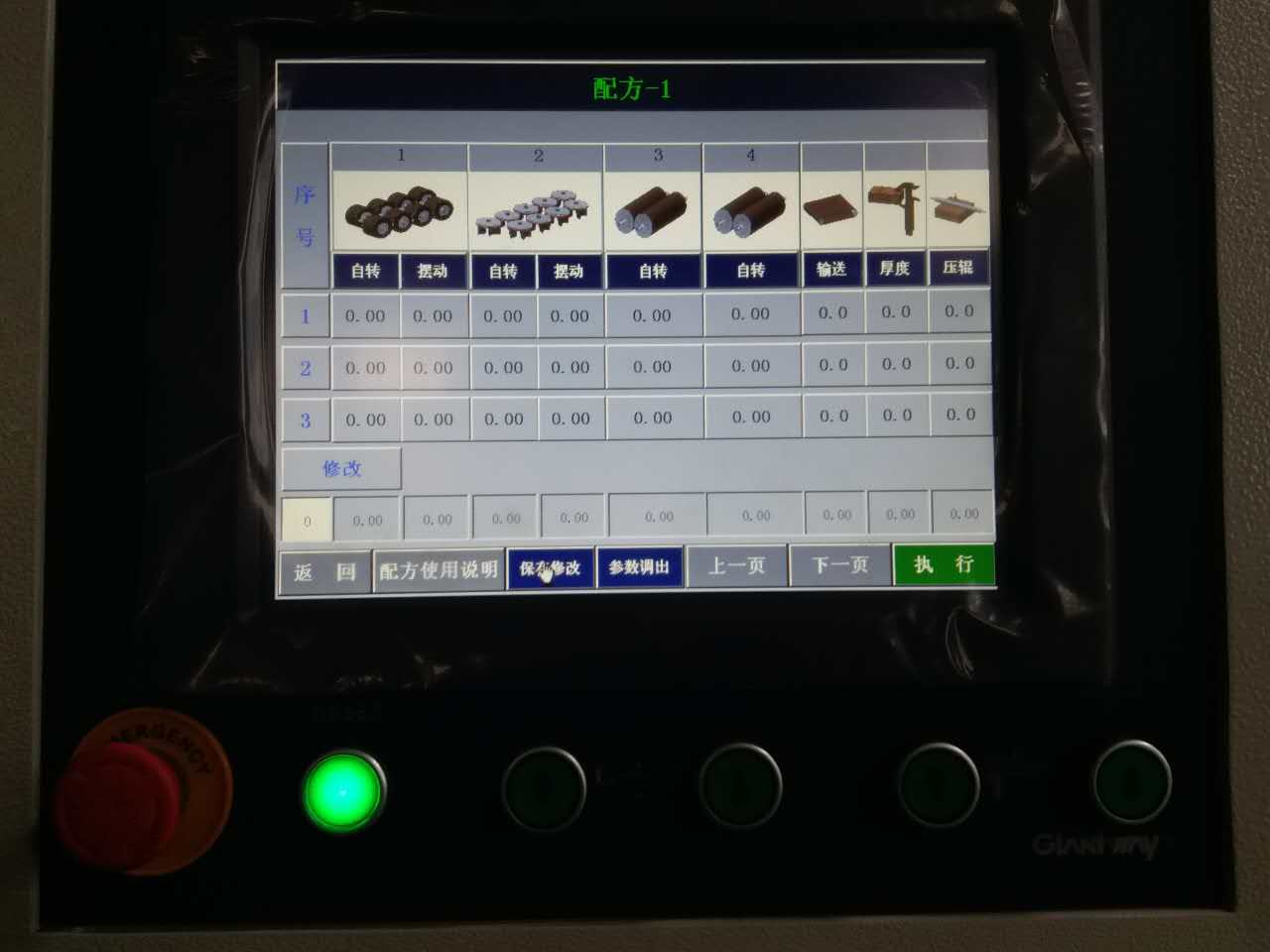

Formula function: fast finding the suitable data for different working parts and can memorize the data and output it quickly to realize high-level automatic machinery.

Perfect Features

1.Mainly suitable for polishing uneven boards, such as furniture, wooden doors, cabinets.

2.With the polishing units of abrasive strips, sisal brushes, the machine can effectively remove sharp wood fibers, burrs, paint accumulation and smooth the painted wood edges.

3.Four individual modular working units.(1)Cross brush rollers: oscillate left and right while rotating. (2)Sanding disc units: rotate and oscillate. (3)and (4) Longitudinal roller brush : rotate and oscillate.

4.Formula function: Memory coding for the polished working parts facilitates the next operation according to storage data. Only inputting the code can achieve height adjustment automatically.

5. Fixed working table with vacuum function and good holding for short boards and slipped boards, to ensure efficient feeding.

6. With high flatness through mirror finishing, the material of the conveyor bed remains stable and excellent precision without deformation when processed by high temperature.

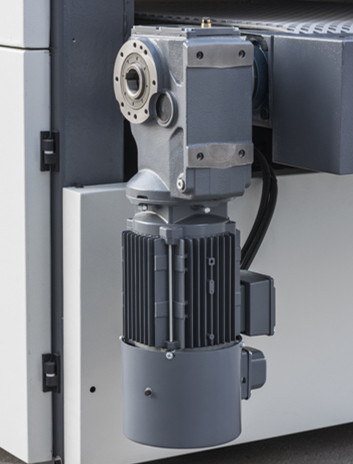

7. High efficiency and quality gearbox, with high quality inverter function.

| 1) Rational structure design |  |

2) Mechanical welding ---Automatic welding by mechanical hand ---Heat treatment |  |

3) Conveyor bed surface ---Mirror finishing ---Flatness within 0.05mm ---Heat treatment by high temperature |  |

4) Control panel 4.1) Overview panel ----Easy operation |  |

4.2) Running panel ----Individual modular operation ----Adjusting the running speed of each unit independently |  |

| 4.3) Formula panel ----Memory code for the processed workpiece ----Inputting the code in the next operation, the machine can adjust automatically according to storage data. |  |

5) Modular brush unit 5.1) Longitudinal roller brush ----Abrasive strips brush the dent parts of workpiece effectively ----An obvious polishing effect on concave and convex workpiece. |  |

| 5.2) Sanding disc brush ---S shaped grinding trace ---Grinding the concave and convex uniformly ---Saving time for replacing the abrasive strip |  |

5.3) Cross sanding roller ---Adjusting height independently ---Adjusting speed independently ---An obvious polishing effect on the longitudinal grain of concave and convex workpiece |  |

6) Bearing ----FSB bearing ----Higher precision ----Simpler maintenance |  |

7) PLC ----Brand DELTA ----Widely used in all electric controller ----Easy maintenance |  |

8) Electric components ----TECO brand from Taiwan ----Quality guarantee |  |

9) Vacuum table device ----Increasing the stability and soundness in the feeding process |  |

10) Gearbox ----High quality gearbox with inverter motor |  |

1) Processed data Max. working width:1100mm Max. Working thickness:100mm Max.working length: not limited

2) Brush unit diameter and quantity Cross sanding brushφ320mm*8 Sanding disc φ180mm*11 Longitudinal sanding brush φ320mm*4

3) Brush unit speed Cross sanding brush Max.550rpm(inverter) Sanding disc Max.500rpm(inverter) Longitudinal sanding brush Max550rpm(inverter)

4) Brush unit oscillating frequency Cross sanding brush Max.30 t/min(inverter) Sanding disc Max.30 t/min(inverter) Longitudinal sanding brush Max.60 t/min(inverter)

5) Conveyor belt Size: 1110*7440mm Speed: 0-19m/min(inverter)

6) Motor power Total motor power:24.61kw Cross sanding brush motor power 1.5kw Cross sanding brush oscillating motor power 0.75kw

Sanding disc motor power 1.5kw Sanding disc oscillating motor power 0.75kw Longitudinal sanding brush motor power 1.5kw*4

Longitudinal sanding brush oscillating motor power 0.37kw*2

Center frame lifting motor power 1.5kw Press roller lifting motor power 0.37kw Feeding motor power 4kw(inverter)

7) Size Dust outlet Φ150mm*4 Vacuum table exhaust outlet outlets Φ200mm*1 Overall dimension(L. W. H):4000x1900x2200mm

8) Weight About 5000kg

Address: Hongxiang Er Road, Jinling Industry Park, Chengyang, Qingdao, 266111, China

Domestic sales:+86-532-87909872

International sales:+86-532-87909872

Mobile/ Wechat/ Whatsapp: +86 13608989908

Fax:+86-532-87909875

www.giantway.com

Email:sales.b@giantway.com